Incremental Encoder Engineer Interview

April 4, 2016

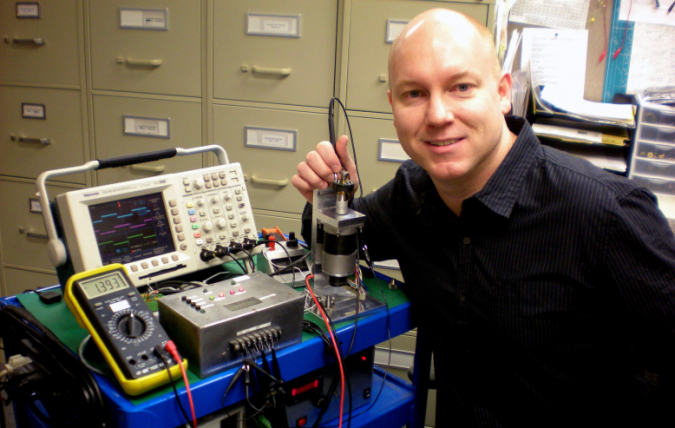

I was featured in an interview with EEWeb.

Jim Miller – Application and Design Engineer at Quantum Devices

How did you get into electronics/ engineering and when did you start?

I started when I was pretty young, like nine or ten, taking apart radios and using an old wood-burning tool to de-solder components from the circuit boards I scavenged. I would pick up anything that was broken or being thrown out and tear it apart. I had no idea what I was doing but eventually stumbled onto some of the “Engineers Notebooks” that Forrest M. Mims III wrote for Radio Shack, those gave me the knowledge I was missing. Before long I was able to blow fuses out in the house on a regular basis. I have come a long way since then – we now have circuit breakers.

Can you tell us about your work experience/ history before becoming an Applications Design Engineer at Quantum Devices?

I have mainly worked with industrial controls for food & beverage, and pharmaceutical companies, which always includes quite a bit of PLC programming. That is why you will see a bit of ladder logic in with some of the Quantum Devices blog posts that I do. While I predominantly work with discrete electronics today, the industrial controls experience dovetails nicely with our optical encoder lines. Encoders are used on the back of motor and often in industrial applications, so I am able to better understand the way an end user might be trying to implement a design, and to some extend the way they might think.

What have been some of your influences that have helped you get to where you are today?

I honestly think that everyone you come in contact with in life puts a certain spin on your perspective, but if I step back from that idealism the person who most stands out is Todd Martin, another engineer here at Quantum. We tend to drive each other crazy, but I fully respect his intellect and abilities. He is always seven steps ahead of the game and has a wide knowledge of electronics; from the processes used to build components through to their limitations in implementation. He can do more with a pencil and paper than most engineers can with a computer. There is a huge amount of technical knowledge I have picked up from him, but probably the most significant thing I have learned from Todd is how to fully document and summarize data to support the facts I am trying to show. This also serves me really well outside of the workplace, whenever I need to negotiate over the work done by a contractor or repairman.

What are your favorite hardware tools that you use?

Probably some of the encoder testing equipment I have designed and built.

What are your favorite software tools that you use?

I use excel all the time and love it’s flexibility to massage data and port it in and out of other programs. I use the Microsoft Studio Suite for a lot of the C++, VB, and Web related things I need to do (HTML, PHP, MySQL).

What is the hardest/trickiest bug you have ever fixed?

For industrial encoder related problems, electrical noise and grounding issues are usually the trickiest. The best solution is usually very simple “provide a better ground to your motor”. But in practicality there are many times when the customer is limited in what they can do. They look to us to solve the problem by changing our encoder design, or the way it is wired. Usually this is done with termination resistors that load the encoder outputs, swamping out the noise, but in a few cases the problem is because the customers ground already has a lot of noise on it, so removing the ground connection from the motor or encoder makes a positive difference. A lot of the challenge is that it is counterintuitive solution to what the customer expects. Instead of telling them to ground something to get rid of noise you are telling them not to.

What is on your bookshelf?

I have a lot of books, but right now I am reading; “Drupal Pro”, “Beginning Tagalog” and a book on Ubuntu Linux that I can’t remember the name of… although I do know myself well enough to know that It’s probably just called “Ubuntu Linux” and I am overthinking it.

Do you have any tricks up your sleeve?

The one I like to use with my friends who know enough just about electricity to be dangerous, is to check for a blown fuse in a live circuit with a Voltmeter. Most people know how to check for a blown fuse by pulling the fuse out, setting the DMM to continuity and listening for a beep, but they don’t really understand how measuring the fuse in a live circuit you will get a voltage drop through the meter if a fuse is open and little or no voltage across it if it’s intact. I usually get a confused, doubting look whenever I do this.

What has been your favorite project?

This one wasn’t what I would call a major project, but it was enjoyable, and comes to mind… Not too long ago I was asked if I could use my industrial control knowledge to build an electrical panel that would control an indexer for one of the CNC machines in our shop. The implementation was really smooth and helped to shave a great deal of cycle time off of a drilling operation. It also freed up an operator who had to stand at that machine and rotate the part after every pass of the drill. It is nice when you know your efforts are immediately appreciated like that.

Do you have an experiential stories you would like to share?

I have two. While in college I was messing around breadboarding a homebrew audio amplifier. After burning up a few expensive power transistors I learned to started out with the voltage fairly low like setting the rails to +/- 5V or something, then after everything checks out, bring the voltage up from there. A short while after turning the voltage up I started hearing this high pitch whining sound. I just had a dummy load of power resistors hooked up and no speaker, so I had no idea as to what might be causing the sound. I leaned in really close and took a look at the components on the breadboard but didn’t see where the culprit was, as soon as I leaned back in my chair to grab a scope probe a capacitor blew up. The aluminum cover of the cap had hit the ceiling like a bullet, knocking a divot out of the plaster and there was that terrible smell of electrolytic in the air. I was in a bit of shock because I just had my face over that capacitor only a moment before. When I looked at what was left of the aluminum cover to the capacitor I realized that the working voltage on the capacitor was 15VDC, but I had the power rails turned up to +/-40 Volts.

The other story has nothing to do with electronics, but was a very cool experience. When I was leaving town one day I noticed that there was a woman clinging to the outside of the fence on the overpass of the highway. It was pretty clear she was trying to kill herself, so I decided to stop and try to talk her out of it. I am not sure what made me stop, or think that I could talk her out of it, but for some reason I just felt certain I could. When I approached her I noticed that there were crude bandages on her wrists where blood was coming through. Before coming to the overpass she had apparently slit her wrists and rebandaged them. I remember the look in her face as I approached her, she seemed to be both ready to talk to me and yet there was some fear there, like she was worried I was going to scold her. I can’t remember exactly what I said to her to open our conversation, but I think it was something like “It looks like you are having a bad day.” She was willing to talk, but was not willing to come down. After about 15 minutes the police showed up, so I stepped back to let them take over, but she wasn’t willing to talk with them, she only wanted to talk with me. At the time I though it was due to the small amount of rapport we had built up, but later I realized it was more likely the previous experiences she had had with the police. I went back to the fence and stood there listening to her talk about the things that were troubling her, trying to redirect her to the positive things in her life. looking over her shoulder to the distance I could see the flashing lights and backed up traffic where the police had set up a roadblock. They had shut the highway down in both directions. After 20 minutes of her clinging to the fence and not moving, I realized that there were two ways this could end and I was very worried that things might not turn out the way I had initially expected. It was windy and I was trembling from the cold, and I wondered how long she could hold onto that chain link fence before she had to let go. I told her that I needed to sit down and made my way to a concrete barrier where the fence ended and asked that she come and sit with me. When she eventually did, the police wrapped a blanket around her, then escorted her to the ambulance and took her away. A few weeks later I received a thank you note from her written in very shaky handwriting. It was the only card I have ever received that started with “thank you for talking me off the bridge…” I felt good about the experience afterward, but often wonder how I would have felt if things had ended differently.

What are you currently working on?

We are kicking around some designs for a low cost commutation only encoder. I am also working on a side project at home that would streamline our RMA process. It will eliminate a lot of duplication of effort, and allowing for some better real time information and querying. And there are always product and process improvement projects we are working on.

What are some of the major changes Quantum Devices has seen since its founding in 1989?

The company started out with sensor, photodiode and LED manufacturing as its main focus then eventually shifted into putting these pieces of silicon into their own products, like encoders and LED lighting. A recent very sad event for the company was the passing of our founder Ron Ignatius. He was a dynamic visionary with a strong will and conviction, that is not seen in business today. His passing was a great loss, but his spirt and dreams live on today in the work we do.

What direction do you see your business heading in the next few years?

For our optical encoder product lines there seems to be a continuous push for smaller and smaller devices and a simultaneous need for increasing line counts, but this pressure has always been there, so we are sort of in tune with it. I am guessing that the light and sensor product lines we have will experience the most change and growth, as LED lighting is becoming a very hot industry right now.

What challenges do you foresee in our industry?

As for our industry I feel that everyone is still a bit nervous about our economic environment, so there won’t be as great of a push for new designs as there will be for cost cutting. As far as electrical engineering in general, I often get concerned about whether or not we will have an ample supply of young minds interested in our field. It seems that there is a big interest software side of things, but I don’t see many kids geeking out on electronic hardware. If I were 13 today I would be tearing apart an iPhone or an old Gameboy, I just don’t see kids doing that kind of thing.

What are some of your hobbies outside of work and design?

I play on an City League Basketball team, which serves as a nice motivator to never let myself get too far out of shape. I enjoy computer programming and spending time with my family.

Is there anything that you have not accomplished yet, that you have your sights on accomplishing in the near future?

I always have a small goal list going, (Put siding on the house, create a new computer program for my brother-in-law’s record keeping, learn Tagalog) but as far as the big hairy audacious goals, the ones that you really have to map out, I am in between goals right now. I am taking my time to recognize an opportunity that is worthy of pursuit. I think the goals I decide pass on are more important that the ones I choose to go for.

Related article: An interview with Samantha Lundt, one of QDI’s process manufacturing engineers.