QM22 servo motor encoder with integrated commutation outputs

Servo motors coupled with encoders are widely used and projected to grow in popularity due to increasing automation, more stringent standards for energy efficiency, and advances in servo system technologies. As the servo motor market becomes more competitive, OEMs are demanding reliable servo motor encoders in a small format for a fair price.

Quantum Devices has designed a range of servo motor encoders to provide the most reliable signals with a simple assembly process and larger allowable tolerances. Our high-performing servo motor optical encoders are reliable, affordable, forgiving and designed with customers’ needs in mind.

Browse encoder products or contact a Quantum Devices engineer for more information. We can provide custom configurations, and free encoder samples are available for qualified projects.

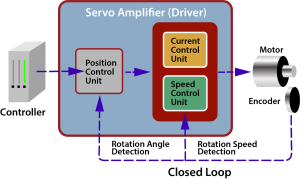

A servo motor (aka servomotor) is an electric motor used in a servomechanism, a device that uses a closed-loop control circuit to automate mechanical motion. Along with the servo motor, the other components of a servomechanism are the servo amplifier (driver), encoder and controller.

Servomechanisms move machine parts with a high degree of accuracy and are used in a very wide range of industrial applications such as CNC machine tools, antenna rotators, conveyor belts and automated guided vehicles.

A servo motor encoder detects the rotation angle, speed, and travel distance of a moving machine part and sends positional feedback to the controller. The controller sends electrical signals to the driver, which amplifies and translates the signals for the servo motor. The servo motor rotates an output shaft to produce the right torque and velocity to achieve the commanded position.

Diagram of basic servomechanism with closed loop feedback

Unlike stepper motors, which function synchronously with the controller’s pulse signal output, servomechanisms require position feedback for commutation and speed control, and to compensate for disruptions in the motor or load.

Servo motors don’t necessarily need an encoder. Servo motors can also use a potentiometer, resolver or Hall effect transducer as a feedback sensor, typically with less reliability and precision. The optimum sensor for a servomechanism depends on the particulars of the intended application.

There are several aspects of a servo system that determine which servo motor encoder type will work best.

Linear encoders are used to track motion along a straight line, as in a laser scanner or cut-to-length machine.

Rotary encoders (aka shaft encoders) are used when there is rotational movement, as in a robotic arm, milling machine or flight simulator.

Absolute encoders track position using a unique bit of code for every point of rotation. Because absolute encoders can report exact position without homing, they’re used in applications like surgical robots and other instances where re-homing would be problematic.

Incremental encoders track position by using a reference point, which means they need movement to report change in angular position. Servo motor incremental encoders are highly customizable and used in many different motion control applications where re-homing on startup is not an issue.

Solid shaft encoders have a rod which must be matched to the width and length of the servo motor’s actuator dimensions using a mounting flange and coupling. Typically, larger than hollow shaft encoders, solid shaft encoders are commonly used in applications with measuring wheels such as conveyor belts.

Hollow shaft encoders are mounted directly on a servo motor. Hollow shaft encoders that use integral bearings in their construction will use a spring tether, making them more resistant to shock and vibration. Bearingless hollow shaft encoders mount directly to the motor frame. Hollow shaft encoders are ideal for dynamic motor control applications.

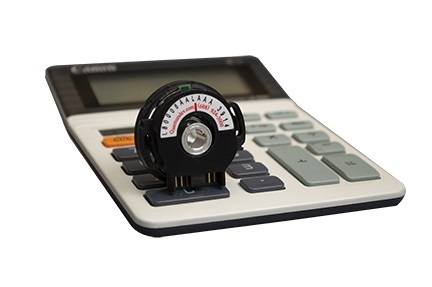

QML35 EZ-Comm encoder

The environmental conditions where the servo motor encoder will be used are an important consideration. Temperature, moisture, shock, vibration, presence of chemicals, particulates or electromagnetic interference can all affect encoder performance. A fully enclosed (IP66) optical rotary encoder such as the QR145 is ideal for use in demanding environments.

Applications in tight spaces may require a compact or low-profile encoder. Quantum Devices offers miniature rotary encoders with built-in commutation, reduced space requirements and low-to-no-noise operating profiles.

The QM22 features a compact design, integrated BLDC motor commutation and is REACH/RoHS compliant. The QM22 was designed to fit on a NEMA 11 BLDC servo motor, reducing the space required for the motor/control package and minimizing cabling requirements.

The QM35 and QML35 low-profile modular incremental optical encoders from Quantum Devices are groomed for high-volume OEM applications and priced competitively for all size servo motors, easily accommodating motor shaft sizes up to 0.375″.

Incremental encoders use an output driver to send digital signals to a readout device. Output driver selection should be based on the voltage requirements of the controller and drive. Without sufficient voltage, the signals can’t be transmitted across the network. Quantum Devices encoders offer versatile electrical configurations and several commutation options.

Incremental encoders measure resolution in PPR (pulses per revolution), where a pulse is the smallest segment of measurement. The higher the resolution (aka line count), the higher the level of granularity in monitoring position change.

High resolution servo motor encoders allow a controller or drive to perform faster, more accurate speed regulation. Choosing the best servo motor encoder resolution requires balancing higher levels of granulation with frequency and application limitations.

The maximum input frequency of electronics interfaced with the encoder will cap the encoder’s speed. As an example, if you have a 6000 RPM application and want to use a 5000 line count encoder, the frequency response will be 500kHz. If the interface electronics are limited to 200kHz, that combination won’t work.

Even with a high-resolution encoder, if the application has a large inertial load, system performance will be limited by the motor’s ability to respond to the commands.

Rather than seeking an encoder with the highest resolution, a better approach is selecting an encoder with the ideal combination of resolution, accuracy and repeatability for a particular application.

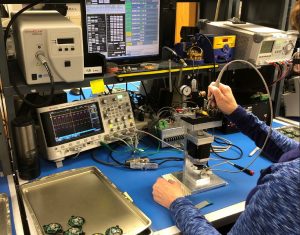

Inside our Wisconsin manufacturing facility

Quantum Devices has for decades focused on full vertical integration of its operations, producing each critical element of our incremental optical encoder product line in house at our facilities in Barneveld, Wisconsin.

For OEMs who are experiencing component supply disruptions, Quantum Devices offers multiple direct encoder replacement options for Renco and other incremental encoder manufacturers, and we have the manufacturing capacity to fulfill your needs.

Quantum Devices has developed a full complement of incremental optical encoders to fit multiple industries and applications. Our engineers can evaluate your motion control application and provide a solution meeting your specific needs. Free encoder samples are available for qualified projects.

Create an account to gain access to all of our 3D models!

Create an account to gain access to all of our 3D models!